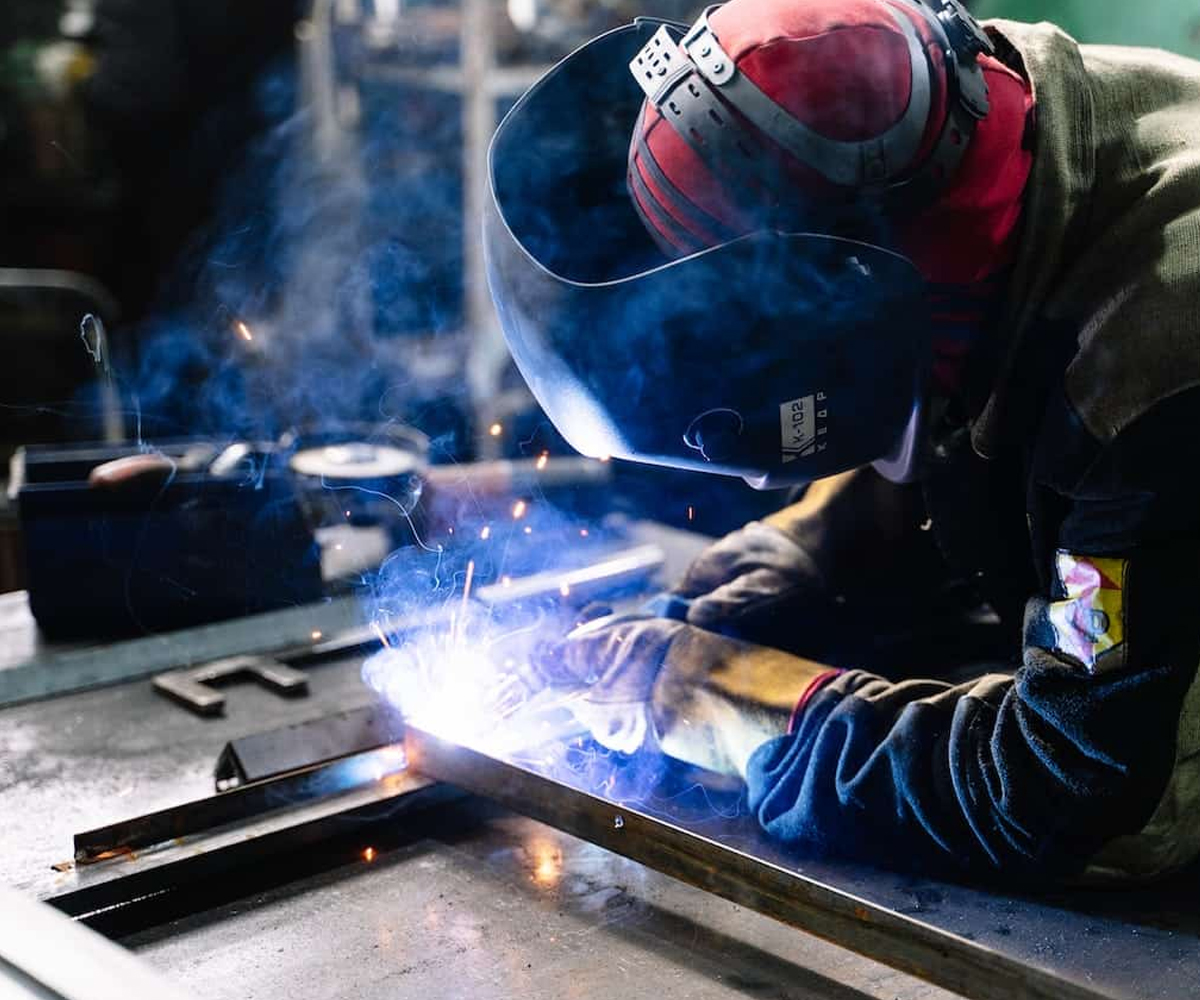

5 Commonly Used Welding Methods

There are several welding methods commonly used in industry. The following is a long explanation of the five methods:

1. Electric Welding

Electric welding is a method that uses electric current to produce enough heat to melt the metal and welding material. In electric welding, there are two main types, namely electric welding with protected electrodes (Shielded Metal Arc Welding/ SMAW) and electric welding without coating (Gas Metal Arc Welding/ GMAW).

In electric welding with protected electrodes, coated electrodes are used to protect the welding area from air and provide filler material. Meanwhile, in uncoated electric welding, welding gas is used to protect the welding area. This method is very flexible and is often used for a variety of metal types and thicknesses.

2. Gas Welding

Gas welding involves the use of a burning gas, such as acetylene gas, as a heat source to melt the metal and welding material. This method is often used to weld thin metals or in situations where the use of electricity is impractical.

Gas welding also allows welding in an open environment because it does not produce a lot of sparks or fumes. This method is generally used in the tank, pipe and construction manufacturing industries.

3. Electric Arc Welding

Electric arc welding is a method that uses an electric arc generated between an electrode and a metal material to produce high heat. The heat produced by the electric arc is used to melt metals and welding materials.

Not much different from electric welding, there are several types of electric arc welding, including electric arc welding with coated electrodes (Shielded Metal Arc Welding/ SMAW), electric arc welding with ionized gas (Gas Tungsten Arc Welding/ GTAW), and electric arc welding with continuous electrode (Gas Metal Arc Welding/ GMAW).

4. Gas Furnace Welding

Gas furnace welding involves the use of a gas furnace to heat the metal and welding material to quite high temperatures. Once the desired temperature is reached, the metal and welding material are combined to form a strong joint as it cools. This method is widely used in the manufacture of industrial equipment that requires welding on a large scale, such as ships, storage tanks and large pipes.

5. Friction Welding

Friction welding is a welding method that involves friction between two metal materials to be joined. This friction produces enough heat to melt the metal and form a joint.

This method is often used to weld non-ferrous metals, such as aluminum and copper. Friction welding has several advantages, including a fast process, good heat control, and high joint quality.